OUR EXPERIENCE AND HISTORY

Founded in 1974, our company offers high-precision manufacturing and engineering solutions for the defense industry, automotive, railway, and special industrial applications with over half a century of experience.

Since its establishment, the company has continuously evolved by transforming all its accumulated knowledge into a more sustainable and systematic structure; becoming a modern industrial organization focused on quality, reliability, and technology. To date, it has signed strong projects both domestically and internationally, producing solutions that add value to its customers.

Our Fields of Activity

- Transmission and power transfer solutions for the defense industry

- Gear, transmission, and drive system components specifically for commercial vehicles

- Connection parts and carrier systems for railway applications

- Forged part production, ring rolling, and heat treatment solutions

- Automatic transmission manufacturing, heavy maintenance, and testing services

Our Production Infrastructure

In our integrated facilities spanning a total of 70,000 m² of enclosed space, equipped with high technology:

- 55,000 m² gear production facility

- 15,000 m² forging production facility

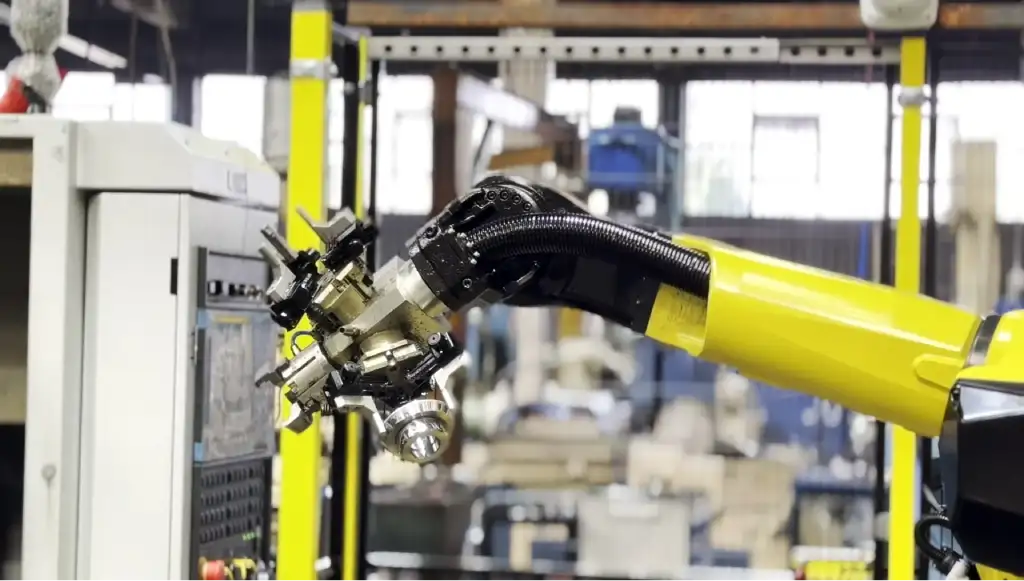

- More than 400 CNC and special production machines

- Robotic production lines in gear manufacturing and high-quality machining capability for bevel, helical, and precision gears.

- Robot-assisted lines for steel forging, producing parts ranging from 0.5 to 70 kg

- Complete production processes including heat treatment, shot peening, and surface coating

- Integrated transmission assembly lines and computer-controlled testing/balancing systems

Strategic Competence

As the sole authorized production and maintenance partner in Turkey under a licensing agreement with the world leader in automatic transmission systems, ALLISON TRANSMISSION, we operate with full authorization.

Within this scope, all the following processes are carried out in a licensed, secure, and integrated manner:

- Part manufacturing

- Product supply

- Transmission manufacturing

- Heavy maintenance and service operations

- Post-assembly quality control and functional testing

Our Quality and Safety Certificates

Quality is not just a result; it is a philosophy underlying each of our products.

Our certifications include:

- ISO 9001:2015 Quality Management System

- IATF 16949:2016 Automotive Quality System

- ISO 14001:2015 Environmental Management

- ISO 45001:2018 Occupational Health and Safety

- ISO/IEC 27001:2013 Information Security

- MSB Production Permit Certificate

- MSB Approved Supplier Certificate

- National and NATO Facility Security Certificates

From Past to Future

With our extensive engineering expertise, strong technical infrastructure, and international collaborations, we act responsibly as a trusted manufacturing partner in many strategic areas ranging from defense industry to automotive.

Shaping the Future with Half a Century of Experience, Making a Difference in Engineering